cold rolled steel strip supplier, precision cold rolled steel sheets processing technology has evolved significantly to meet the growing demand for high-precision, high-performance materials. Among the most widely used products in modern manufacturing are cold rolled steel strips and sheets. Choosing a reliable cold rolled steel strip supplier is essential for industries that require tight dimensional tolerances, superior surface finish, and consistent mechanical properties. In particular, precision cold rolled steel sheets have become indispensable in applications where accuracy and performance are critical.

This article explores the characteristics of cold rolled steel products, the role of specialized suppliers, and the advantages and applications of precision cold rolled steel sheets.

Understanding Cold Rolled Steel

Cold rolled steel is produced by further processing hot rolled steel at room temperature. After the steel has cooled, it is passed through rolling mills to reduce thickness and improve dimensional accuracy. This cold working process increases strength and hardness while enhancing surface quality.

Unlike hot rolled steel, cold rolled steel offers better flatness, smoother surfaces, and tighter tolerances. These qualities make it ideal for precision manufacturing and high-quality end products.

What Is a Cold Rolled Steel Strip?

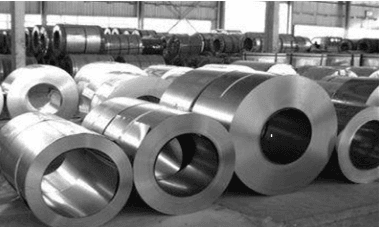

A cold rolled steel strip is a flat steel product with a narrow width compared to its length. It is typically supplied in coils and can be slit into various widths depending on customer requirements. Steel strips are widely used as raw material for stamping, bending, forming, and welding processes.

A professional cold rolled steel strip supplier ensures consistent thickness, smooth edges, and excellent surface finish across every coil.

Role of a Cold Rolled Steel Strip Supplier

A reliable cold rolled steel strip supplier plays a crucial role in the steel supply chain. Beyond manufacturing or distributing steel strips, the supplier ensures that the material meets strict quality standards and customer specifications.

Key responsibilities include:

-

Providing uniform thickness and flatness

-

Ensuring precise width control through slitting

-

Offering various steel grades and surface finishes

-

Supplying coils with proper packaging and labeling

-

Providing quality certificates and inspection reports

An experienced supplier helps manufacturers reduce material waste, improve processing efficiency, and achieve consistent product quality.

What Are Precision Cold Rolled Steel Sheets?

Precision cold rolled steel sheets are flat steel products manufactured with extremely tight dimensional tolerances and superior surface quality. Compared to standard cold rolled sheets, precision sheets undergo additional processing steps such as advanced rolling control, leveling, and surface treatment.

These sheets are typically supplied in cut lengths rather than coils and are designed for applications where accuracy and appearance are critical.

Key Characteristics of Precision Cold Rolled Steel Sheets

Precision cold rolled steel sheets offer several distinctive advantages:

1. Tight Thickness Tolerance

Precision rolling ensures minimal variation in thickness, which is essential for automated production lines.

2. Excellent Surface Finish

Smooth, clean surfaces make these sheets suitable for painting, coating, or decorative applications.

3. High Dimensional Accuracy

Length, width, and flatness are closely controlled, ensuring consistency in final products.

4. Enhanced Mechanical Properties

Cold working increases yield strength and hardness while maintaining good formability.

These characteristics make precision cold rolled steel sheets a preferred choice for high-end manufacturing.

Manufacturing Process of Cold Rolled Steel Strips and Sheets

The production process typically includes:

-

Pickling

Hot rolled steel is treated to remove scale and impurities. -

Cold Rolling

The steel is rolled at room temperature to achieve desired thickness. -

Annealing

Heat treatment restores ductility and relieves internal stress. -

Skin Passing / Temper Rolling

Improves surface finish and controls mechanical properties. -

Slitting or Cutting

Coils are slit into strips or cut into precision sheets.

A qualified cold rolled steel strip supplier closely controls each stage to ensure consistent quality.

Applications of Cold Rolled Steel Strips

Cold rolled steel strips are used across a wide range of industries:

-

Automotive – structural parts, brackets, reinforcements

-

Electrical and Electronics – motor laminations, enclosures

-

Appliances – washing machines, refrigerators, ovens

-

Furniture – frames, shelving systems

-

Construction – profiles, light-gauge steel components

Their versatility and cost-effectiveness make them a staple material in manufacturing.

Applications of Precision Cold Rolled Steel Sheets

Precision cold rolled steel sheets are used in applications requiring accuracy and superior finish:

-

Automotive body panels and interior components

-

Precision stamping and deep drawing parts

-

Electrical cabinets and control panels

-

Medical equipment housings

-

Office equipment and consumer electronics

In these applications, even minor dimensional deviations can cause assembly issues, making precision sheets essential.

Importance of Surface Treatments and Finishes

Cold rolled steel strips and sheets can be supplied with various surface finishes to suit different applications. Common options include:

-

Bright finish

-

Matte finish

-

Oiled or dry surfaces

-

Galvanized or coated surfaces

A professional cold rolled steel strip supplier offers customized surface treatments to improve corrosion resistance, appearance, and processability.

Quality Standards and Testing

Quality assurance is a critical aspect of cold rolled steel production. Reputable suppliers adhere to international standards and conduct rigorous testing, including:

-

Thickness and width measurement

-

Surface inspection

-

Tensile and yield strength testing

-

Flatness and edge condition checks

These measures ensure that precision cold rolled steel sheets meet strict performance and dimensional requirements.

Choosing the Right Cold Rolled Steel Strip Supplier

Selecting the right supplier can significantly impact production efficiency and product quality. Key factors to consider include:

-

Technical expertise and experience

-

Range of steel grades and dimensions

-

Precision slitting and cutting capabilities

-

Consistent quality control systems

-

Reliable delivery and logistics support

A dependable supplier acts as a long-term partner, supporting customers with technical advice and tailored solutions.

Market Trends and Future Outlook

As industries move toward lightweight design, automation, and higher precision manufacturing, demand for precision cold rolled steel sheets continues to grow. Automotive electrification, smart appliances, and advanced electronics are driving the need for steel products with tighter tolerances and improved surface quality.

Cold rolled steel strip suppliers that invest in modern rolling technology and quality management systems will remain competitive in this evolving market.

Conclusion

Cold rolled steel products are essential materials for modern manufacturing, offering superior surface quality, strength, and dimensional accuracy. Working with a reliable cold rolled steel strip supplier ensures consistent performance and quality across applications. Meanwhile, precision cold rolled steel sheets provide the accuracy and finish required for high-end and technically demanding uses.